Bubble Bud Paradise - Much Loved 2 back, H13.5" x W7" x D7", Porcelain, Underglaze, Glaze

Bubble Bud Paradise - Much Loved 2 detail

Peony Paradise front

Birdcage Jar front, 2018

Birdcage Jar-Whichever way the wind blows, 2016, Porcelain, Underglaze, H19" x W16" x D15"

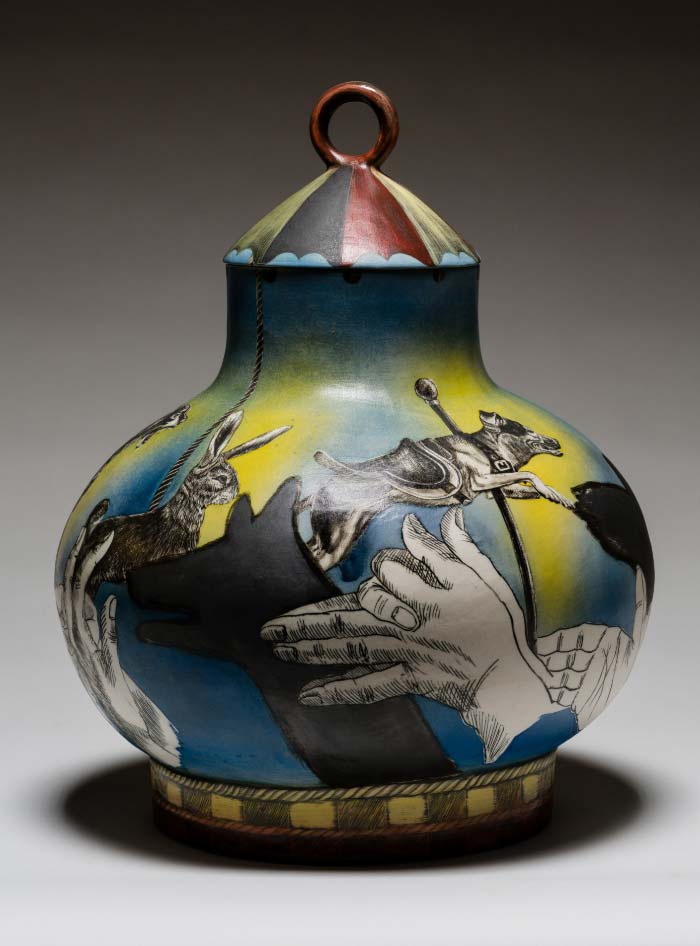

Chasing Shadow Jar, 2016, Porcelain, Underglaze, Glaze H16" x W15" x D15"

Birdcage Jar "The Paradise"-East, 2016, H15.5" x W12" x D12"

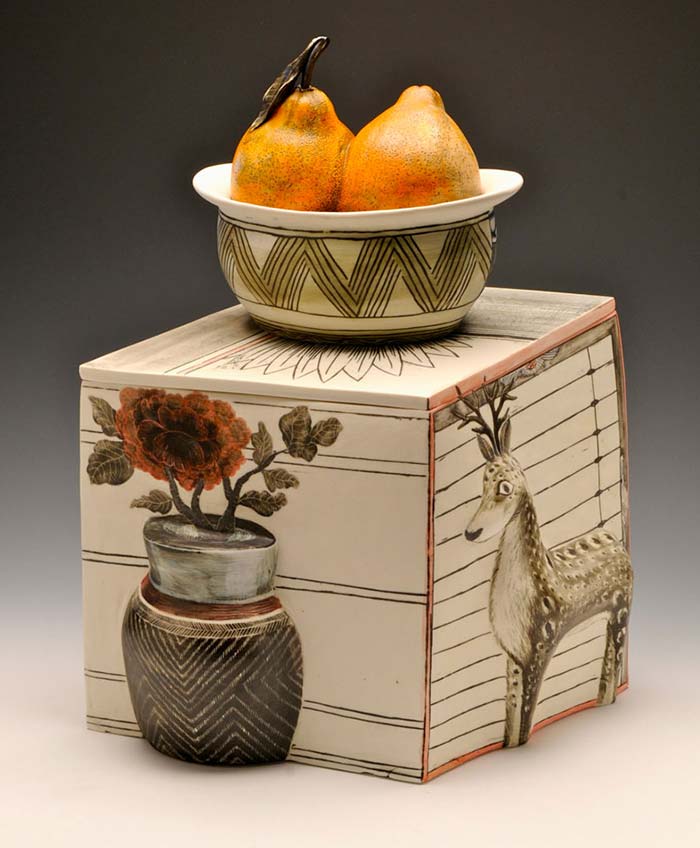

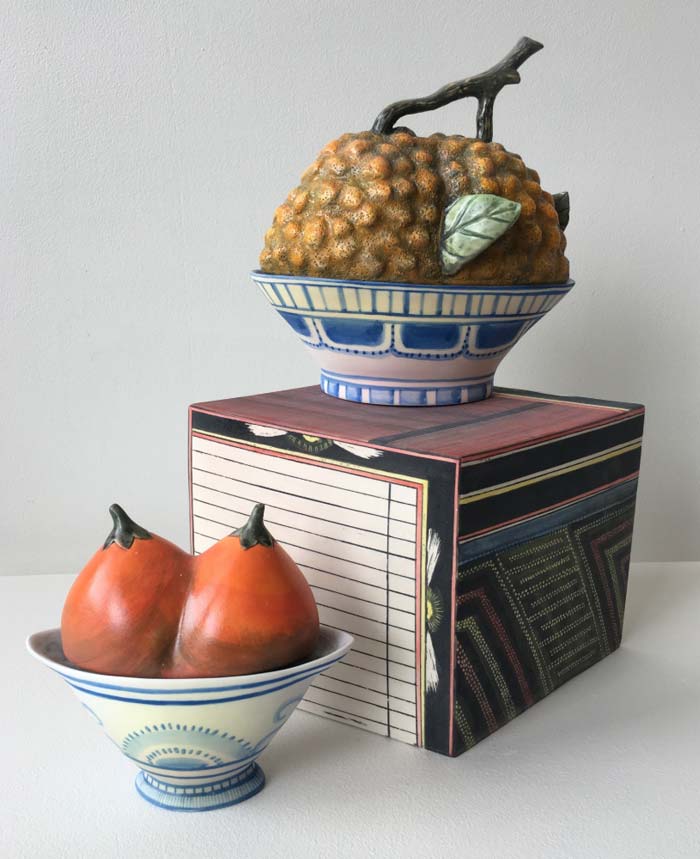

Still Life – East 2013, , Porcelain, Underglaze 16” x 11” x 11”

Still Life East 2 - Tangerine and Persimmon

Dreamlandia-Broken Dream 2013/H16"xW20"xD18"/Porcelain, Underglaze, Glaze, Rubber

Myungjin Kim was born in South Korea. She received her MFA in ceramic art at Seoul National University in 2002 after which she moved to the United States.

MJ has taught Ceramics at Santa Ana College, Cerritos College, University of Georgia, Athens, UGA Study Abroad Program, Cortona, Italy. MJ has taught at California State Univ. Long Beach from 2011 to 2015.

Her work is about human life stories that blend the real and surreal using figuration, animals, vessels and assorted objects. She works primarily with porcelain and most works carry drawn and painted illusionistic imagery. Her ceramic art is featured in private and public collections in both the United States and Asia.

MyungJin Kim