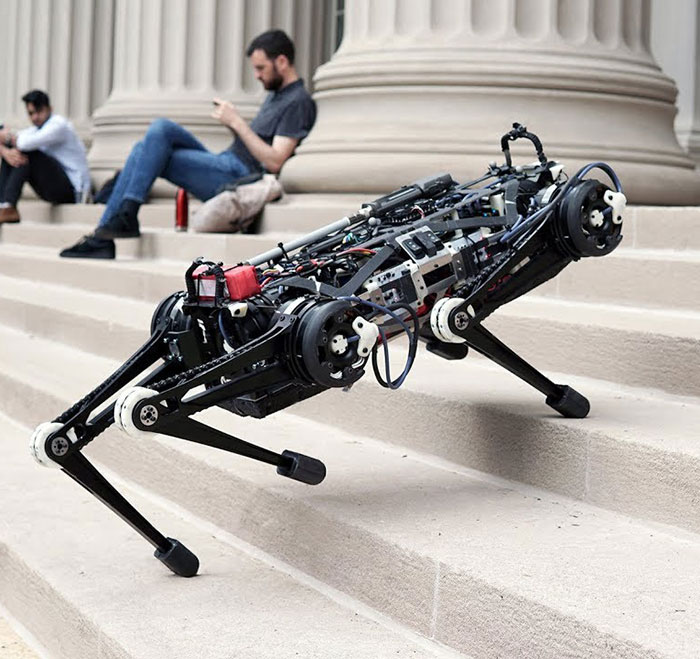

MIT’s Cheetah 3 robot can now leap and gallop across rough terrain, climb a staircase littered with debris, and quickly recover its balance when suddenly yanked or shoved, all while essentially blind.

The 90-pound mechanical beast — about the size of a full-grown Labrador — is intentionally designed to do all this without relying on cameras or any external environmental sensors. Instead, it nimbly “feels” its way through its surroundings in a way that engineers describe as “blind locomotion,” much like making one’s way across a pitch-black room.

“There are many unexpected behaviors the robot should be able to handle without relying too much on vision,” says the robot’s designer, Sangbae Kim, associate professor of mechanical engineering at MIT. “Vision can be noisy, slightly inaccurate, and sometimes not available, and if you rely too much on vision, your robot has to be very accurate in position and eventually will be slow. So we want the robot to rely more on tactile information. That way, it can handle unexpected obstacles while moving fast.”

Researchers will present the robot’s vision-free capabilities in October at the International Conference on Intelligent Robots, in Madrid. In addition to blind locomotion, the team will demonstrate the robot’s improved hardware, including an expanded range of motion compared to its predecessor Cheetah 2, that allows the robot to stretch backwards and forwards, and twist from side to side, much like a cat limbering up to pounce.

Within the next few years, Kim envisions the robot carrying out tasks that would otherwise be too dangerous or inaccessible for humans to take on.

“Cheetah 3 is designed to do versatile tasks such as power plant inspection, which involves various terrain conditions including stairs, curbs, and obstacles on the ground,” Kim says. "I think there are countless occasions where we [would] want to send robots to do simple tasks instead of humans. Dangerous, dirty, and difficult work can be done much more safely through remotely controlled robots.”

The Cheetah 3 can blindly make its way up staircases and through unstructured terrain, and can quickly recover its balance in the face of unexpected forces, thanks to two new algorithms developed by Kim’s team: a contact detection algorithm, and a model-predictive control algorithm.

The contact detection algorithm helps the robot determine the best time for a given leg to switch from swinging in the air to stepping on the ground. For example, if the robot steps on a light twig versus a hard, heavy rock, how it reacts — and whether it continues to carry through with a step, or pulls back and swings its leg instead — can make or break its balance.

MIT's new mini cheetah robot is the first four-legged robot to do a backflip. At only 20 pounds, the limber quadruped can bend and swing its legs wide, enabling it to walk either right side up or upside down. The robot can also trot over uneven terrain about twice as fast as an average person's walking speed.

Mini cheetah is the first four-legged robot to do a backflip

MIT's Mini Cheetah robots play soccer

Sangbae Kim